How dust collector and filter work?

1, Ever wondered how industries are working to cut the air pollution effects caused by them?

Gas and dust came out of the factories and industries as hazardous emissions, which contribute to the release of carbon dioxide gas into the atmosphere. And the main sources of these emissions are the equipment used in various parts of the factories.

These emissions contribute more than 50 percent to the production of greenhouse gases, they contaminate water, air, and soil. To counter these issues, Industries collect emissions by using dust collector systems. These collectors consist of filtration systems.The filter provides a way to control air pollution, which was as per the environmental and workplace safety requirements.

2, But how the dust collector and filter work?

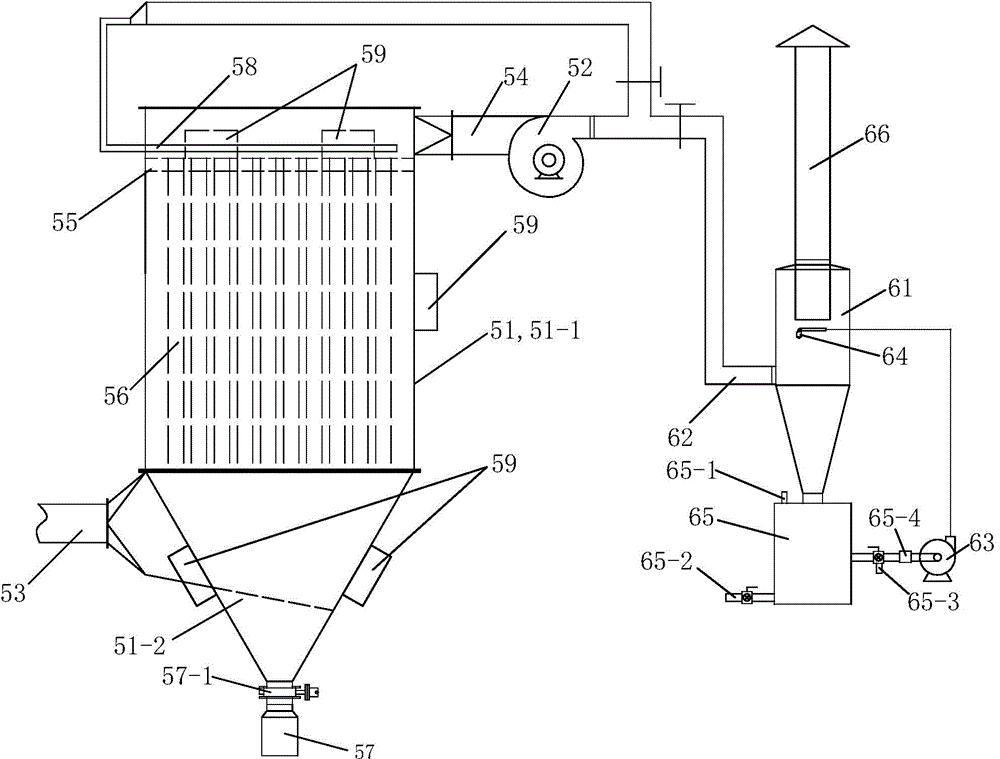

The emissions produced by the factory depend on its products, and the design of the dust collector depends on the extracted materials. The system is used to capture and separate dust, particles and air. It also provides a way to discharge dust-free air. The purpose of each design application is the same. Filters, separates and captures dust and particulate matter and releases sterile air.

Dust collector is a combination of various parts, these parts include blower, filter, dust removal system and filter cleaning system. In order to perform filtration, a bag filter is usually used. The system includes filters, separators, scrubbers and filters. These ingredients can better remove impurities.

3, What is a filter bag and how it works?

In most cases, the use of the filter depends on the material of the filter and its application. The filters listed below are the ultimate choice for various industrial applications.

- Reversing airbag

2. Filter bag

3. Filter socks

4. Filter media bag

5. Tubular bag

6. Dust bag

7. Woven bag

8. Fiberglass bag

9. Fabric filter bag

10. Bag filter bag

The efficiency of filter bags of various design categories is as high as 99%. The main purpose of the bag filter is to purify and remove residues in dust and other particles. From the inside to the outside, these filters are like cartridge filters. The purification of the residue depends on the construction and material of the filter. The bag filter is connected to the pressure inlet and the filter outlet. The filter in the dust chamber uses high pressure to collect dust. The dust-containing gas passes through the filter under pressure. The remaining solid remains in the bag, and the purified air is removed.

Due to the high pressure, a metal or plastic cage is attached to the bag to hold the bag in place during the filtration process. Dust collection capacity is an important parameter for filter design. The antifouling ability of the bag depends on the structure of the bag.

Mesh or single-layer, multi-layer or pleated are different configurations of the bag. For example, pleated bags have the largest filtration area. The bag filter is suitable for non-critical waterborne applications. It is easy to handle bags and solids using bag filters.

Hengke is a China trusted manufacture and supplier for dust filter bag in various countries. Hengke has designed and produced all types, sizes, and configurations of dust filter bag for more than 20 years. Being in the business for two decades, the company offers a wide range of products including dust filter bag, needle punched felts, dust collector bag, filter fabric, filter bag cage, Pulse valve etc. Till now, our products have been successfully exported to over 35 countries.