What is a pulse jet bag filter?

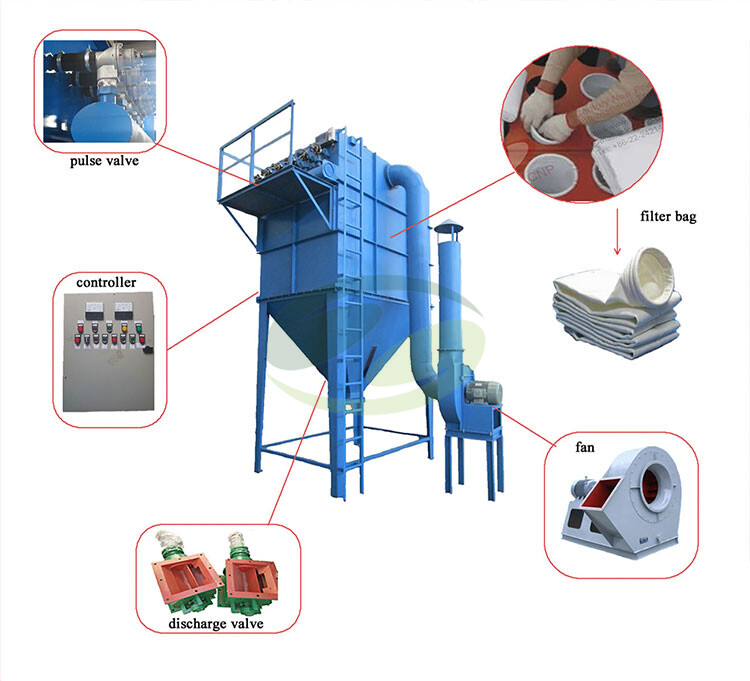

A pulse jet bag filter also called a pulse jet Baghouse or pulse jet dust collector is a self-cleaning dry filtration system. The pulse jet dust collector cleaning system removes particulate and mud from the surface of internal filter media with bursts of compressed gas. Pulse jet bag filters are the foremost common sort of particulate pollution control equipment found in workplaces including factories, plants, warehouses and other industrial or commercial environments, to satisfy workplace air quality safety requirements and suits EPA requirements for emissions.

The pulse jet dust collector contains no moving parts, thus offering reliable continuous operations alongside superior filtration efficiency, engineered to effectively collect and take away potentially harmful particulate gas fumes that might otherwise enter the work environment or atmosphere. The recognition of the pulse jet sort of dust collector is thanks to its simple operation, low energy usage, and minimal maintenance requirements.

Pulse jet bag filters get their name from the short bursts or “pulses” of compressed gas wont to clean the bag or filter. Within the pulse jet system, the dust is collected on the external surface of the bag/filter, where it commonly forms into a cake of dust. Either on a timed basis or supported pressure drop when the dust cake is at an appropriate thickness, a controller activates a sequential pulse of compressed gas into the inside of the filter bags, one (or more) row(s) at a time, knocking the dust and mud cake freed from the filter to fall via gravity into the hopper for removal.

The mechanics of the compressed gas pulse and associated induced draft of additional air through a venturi nozzle create a blast wave and ripple effect on filter bags which reinforces the mechanical force of the initial blast of compressed gas itself, to dislodge the dust particles off the material.

Advantages

Pulse jet bag filter system offer several advantages over other sorts of dust collection systems. The elemental advantage is within the pulse jet’s ability to wash on-line. The duration of the pulse of compressed gas is usually within the range of 100 to 200 microseconds, effectively facilitating 24/7 operations without interruption to the ventilation of dusty air, and no shut-down period to wash the bag filters.

The pulse jet collector is incredibly versatile in terms of the range of temperatures, pressures, and gas stream chemistries with which it finds application. CPE Filters’ pulse jet dust collectors are offered during a broad range of styles with either a top or bottom/side bag loading configuration, cylindrical or square/rectangular housing style, and a good range of filter media options, both bag type and pleated media. Pulse-jet dust collectors could also be fabricated from a good selection of metals—carbon steel, chrome steel, aluminum, or special alloys like Inconel and Hastelloy—to meet the precise needs of any manufacturing environment, starting from chemical compatibility to abrasion resistance to food-grade or FDA requirements.

High collection efficiency serves to solidify the position of most installations for pulse jet bag filters because the most used dust collector in industry. Manufacturing environments like chemical and mineral extraction plants, grain mills, food processing plants, steel mills, metalworking and fabrication shops, asphalt plants and lots of other industries all enjoy pulse jet bag filters to take care of air quality and meet EPA safety standards.

Selection of pulse bag filter

1. Selection of filtering speed:

- The filtering speed is that the key thing about the choice of pulse bag filter. It should be determined consistent with the properties of dust or dust, application occasion, particle size, viscosity, gas temperature, moisture content, dust concentration and different filter materials.

- When the particle size of dust is finer, the temperature and humidity are higher, the concentration is higher, and therefore the viscosity is larger, the low value should be chosen. If < 1 m/min, conversely, the high value shouldn’t exceed 1.5 m/min.

- For dust with large particle size, normal temperature, dry, non-sticky, and really low concentration, 1.5-2 m/min are often selected. When selecting filtration speed, it should be calculated that internet filtration wind speed shouldn’t exceed the above values when reducing the filtration area of 1 chamber (when cleaning ash).

2. Filtration material:

- It should be considered consistent with the temperature, moisture content, acidity, alkalinity, viscosity, concentration and grinding pecking of dust gas.

- Generally, when the water content is little and there’s no acidity, it’s chosen consistent with the temperature of dust gas. At temperature or < 130 C, 500-550 g/m2 polyester needle-punched felt is usually used. When < 250 degree C, Aramid Nomex needle felt or 800g/m2 optical fiber needle felt or 800g/m2 weft double optical fiber fabric or FMS heat filter material (fluorine gas can’t be made from optical fiber material).

- When the moisture content is large and therefore the dust concentration is high, water-proof, oil-proof filter material (or dew-proof filter material) or membrane-covered filter material (the base cloth should be needle-punched felt after waterproof treatment) should be selected. Ryton polyphenylene sulfide (Ryton PPS) needle-punched felt is usually used when the dust-containing gas is acidic and alkaline and therefore the gas temperature is a smaller amount than 190 degrees C. P84 (polyimide) needle-punched felt is chosen when the gas temperature is a smaller amount than 240 degree C and therefore the requirement of acid and alkali resistance isn’t too high.

- When the dust-containing gas is flammable and explosive gas, anti-static tapestry is chosen. When the dust-containing gas has certain moisture and is flammable and explosive gas, water-proof, oil-proof and anti-static (three-proof) tapestry is chosen.

3. Controller:

- The dust cleaning control of pulse bag filter adopts PLC micro-computer programmable controller, which is split into three control modes: constant pressure (automatic), timing (automatic) and manual.

- Fixed pressure control: consistent with the set pressure difference control, the pressure difference of the dust collector exceeds the set value, and every room automatically cleans the dust just one occasion successively.

- Timing control: consistent with the set time, every other cleaning cycle, each room successively cleaning once.

- Manual control: Manual control are often used on the sector cabinet to automatically clear the dust in each room successively, or to separate the dust in each room. The control mode is chosen by the user. When the user has no requirement, the availability are going to be controlled regularly.