The resistance of the dust bag filter is composed of many reasons.

The dust removal equipment itself will have a part of the resistance, and the other resistance is formed by external reasons. What causes the increase in the resistance of the dust bag filter? Let’s Let’s do a detailed analysis.

1. Is the dust bag filter design structure planning reasonable?

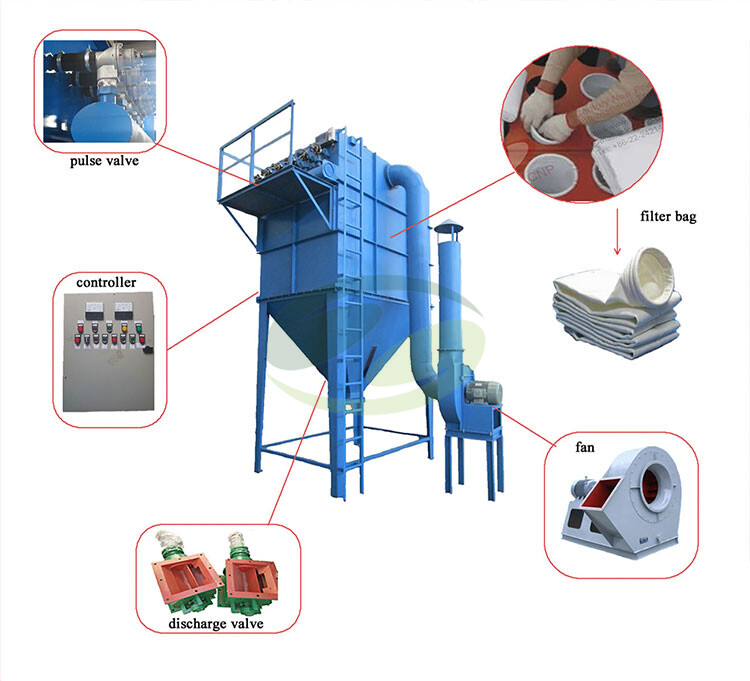

Including the inlet and outlet pipe sections, large bag dust collector, wind turbines, the cross-sectional dimensions of the various components through which the airflow passes, and the planning of locking air, access door seals and equipment insulation. Unreasonable structural planning will make the equipment operation resistance high, and reasonable structural planning has a body resistance of about 400pa.

2. Dust concentration

When the dust concentration is too high, the collision probability between particles increases, and the particles stick together, which also affects the running resistance of the bag filter. At the same time, the addition of concentration means that the thickness of the dust attached to the unit area of the dust filter bag will be added in a unit time, and the pressure loss that has occurred will also be added. In this case, the cleaning frequency is often used. The equipment works normally, but this will increase the frequency of filter bag expansion, strengthen the friction between the filter bag and the bag, reduce the service life of the dust filter bag, and make the filter bag ineffective.

The failure of the filter bag will cause the pressure of the filter bag to be lost and added, and has a high resistance to the operation of the equipment. In addition, the positive pressure gas recoil in the dust removal process is also one of the reasons for the high resistance of the bag filter. Frequent injection of positive pressure gas into the bag chamber will inevitably increase the operating resistance of the equipment. Therefore, when the dust concentration is too high, windshield homogenization equipment should be added to the air inlet pipe and ash hopper for pre-powder treatment to reduce the dust bag filter load of the bag filter and reduce the resistance of the equipment.

3. Dust particle size

The main influence of dust particles from bag filter on bag filter is pressure loss and equipment wear. The pressure loss is fine dust, which can block the filter gap, reduce the permeability of the filter material, and add resistance. It is generally believed that needle-like crystal particles and flake-like particles tend to block the filter bag, reduce the dust removal power, and increase the running resistance. For dust-containing gas containing finer particles, membrane filter bags should be used, such as cement kiln tails, slag grinding systems, etc.

4. Humidity

The gas generally contains a small amount of water vapor. When the relative humidity is between 30% and 80%, it is a normal condition, and when it exceeds this scale, it is a high humidity condition. When the gas in the bag filter is in a high humidity condition, condensation occurs under the effect of the external cold air, which causes the dust to adhere and block the filter bag, and then reduces the dust collection function of the filter material.

It is difficult to clean the dust and the equipment pressure will be reduced. Add accordingly. Regarding condensation, it is generally preferable to select a filter material with a smooth surface, such as a membrane filter. In addition, the outstanding equipment insulation and the addition of dusty gas inlet temperature can reduce the negative effects of cold air and prevent condensation.

5. The permeability of the filter material

Under normal circumstances, the pressure loss of cleaning the dust filter cloth is relatively small, and the air permeability is high. At work, the small loss of pressure means that his pores are relatively large, and the dust is easy to soak. Under normal circumstances, dust will not be trapped. It is relatively low.

In addition, the pressure loss of the dust layer on the surface of the bag filter bag is one of the factors that affect the pressure loss of the filter bag. This is related to whether the filter cloth holes are blocked. Therefore, it is required that the filter cloth holes are not easily clogged, and the dust collection rate is high. The pressure loss is small, the cleaning performance is good, and the service life is long.